Supply chain management is critical for businesses to deliver products and services to customers efficiently. An optimized supply chain reduces costs, improves customer satisfaction, and provides a competitive advantage. The following are some effective techniques and strategies for managing your supply chain.

Optimizing Inventory

Carrying excess inventory can tie up working capital and incur unnecessary storage, handling, and management costs. To optimize inventory, businesses should employ several techniques, typically with the help of software such as that found at technologyevaluation.com.

Demand forecasting uses historical sales data and predictive analytics to determine expected product demand. This feeds into inventory optimization models that calculate ideal stocking levels across the supply chain.

Just-in-time (JIT) inventory systems are also effective, where raw materials or components arrive just as they are needed in the production process. This reduces warehousing needs. Lean manufacturing principles minimize work-in-process and finished goods inventory in the pipeline.

Cross docking can also reduce the need for storage, where shipments are immediately unloaded from incoming trucks and loaded directly onto outbound trucks.

With optimized stocking levels, businesses can meet customer needs while reducing inventory carrying costs.

Improving Logistics Efficiency

To maximize customer service and minimize logistics expenses, companies must optimize their transportation networks, warehouse locations, and distribution plans. Consolidating less-than-truckload shipments into full truckloads improves economies of scale.

Route optimization tools help determine the most efficient delivery sequences, and planning daily delivery runs can make routes more predictable.

Right-sizing fleets, evaluating make-versus-buy decisions, and balancing external carrier costs also help control expenses. Strategically locating regional warehouses and fulfillment centers close to suppliers, production facilities, and end customers can significantly improve lead times and responsiveness.

Implementing contingency plans for rerouting or shifting inventories in case of localized disruptions also contributes to network flexibility and resilience. With logistics optimization, businesses can deliver customer orders faster, more reliably, and at lower costs.

Leverage Technology

Implementing the right supply chain management software and analytics provides real-time visibility into inventory levels, production schedules, shipments, and any delays. This enables data-driven decision-making to identify and quickly resolve bottlenecks before they become big issues. Supply chain technology includes the following options.

- ERP systems that integrate planning, purchasing, manufacturing, sales, and inventory management provide a holistic view of the entire supply chain.

- Warehouse management systems (WMS) that use barcode scanning, inventory tracking, and automated pick-and-pack solutions to operate warehouses efficiently reduce labor costs and errors.

- Transportation management systems (TMS) that provide shipment visibility, freight booking, routing optimization, and carrier management reduce shipping times and costs.

- Supply chain analytics and reporting to uncover insights will improve efficiency and costs. KPI monitoring also helps assess performance.

- IoT sensors on equipment, trucks, containers, and more monitor status, conditions, delays, maintenance needs, and other factors. AI can analyze this data to predict issues and mitigate risks.

- Planning tools like demand forecasting, inventory optimization, and production scheduling align supply with demand to reduce waste and stockouts.

- Automation via robotics, conveyor systems, and automated storage and retrieval systems reduces labor costs and accelerates fulfillment.

The latest supply chain technology makes the procurement, manufacturing, and delivery process nimble, efficient, and intelligent. Combined with strong supplier collaboration and optimization best practices, supply chains can achieve maximum productivity and competitive advantage.

Implementing Lean Techniques

Lean principles help create smooth, waste-free supply chain operations. Techniques like continuous improvement (kaizen) encourage incremental advances through small daily changes. Cross-training employees and empowering them to fix problems quickly also improves agility. Just-in-time production synchronizes actual customer demand so that materials arrive for assembly exactly when needed.

Kanban systems use visual signals to trigger actions, keeping work-in-process inventories low. Total Quality Management boosts quality and reduces defects through practices like Six Sigma statistical controls. 5S organizational methods and mistake-proofing (poka-yoke) also eliminate inefficiencies.

By applying lean techniques, companies can improve productivity, speed, quality, and flexibility across their supply chains.

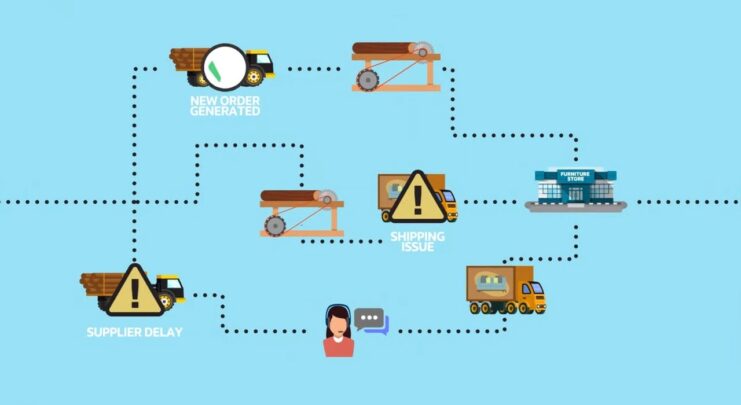

Building Resilience

Supply chains must be resilient enough to maintain continuity despite disruptions. Some effective resilience-building ways include identifying critical failure points and developing risk management plans. Companies should qualify backup suppliers to diversify sourcing.

Increasing inventory buffers for essential materials provides a hedge against short-term shocks.

Building in redundancies, such as multiple production facilities or transportation routes, maintains workflow during localized outages. Managing strategic stock reserves and employing emergency sourcing are useful contingency measures.

Supply chain simulation models can identify vulnerabilities and quantify recovery times from various scenarios. With enhanced visibility, flexibility, redundancy, and a culture of resilience, companies can minimize the impact of supply chain disruptions when they occur.

Collaborate With Suppliers

Maintaining strong collaborative relationships with suppliers is crucial for smooth supply chain operations. Some effective ways to collaborate include:

- Share demand forecasts, production plans, and inventory targets to gain visibility across the supply chain. Suppliers can plan capacities and raw material stocking levels accordingly.

- Implement vendor-managed inventory (VMI) where suppliers monitor and replenish inventory. This shifts the workload away from your business.

- Establish contractual agreements around quality, lead times, transparency, costs, and delivery reliability. This aligns expectations and ensures accountability.

- Implement just-in-time inventories and flexible sourcing. Suppliers can rapidly adapt to changes in requirements.

- Openly communicate potential production issues, anticipated delays, new product launches, inventory targets, and more. Suppliers appreciate transparency and can respond promptly.

- Involve key suppliers early in product/process designs. Their expertise can improve quality and manufacturability.

- Share data via integrated IT systems like ERP software. Doing so provides suppliers with real-time visibility for quick action.

- Develop contingency plans together for supply disruptions, labor issues, natural disasters, and emergencies to build resilience.

- Consolidate suppliers where possible to streamline management and take advantage of bulk discounts. However, avoid sole sourcing risks.

- Encourage environmental responsibility and ethical behavior through supplier codes of conduct to enhance transparency and compliance.

By synchronizing operations, collaborating openly, and building trust, suppliers become invaluable partners for success. Aligning goals and sharing information is the key to a world-class supply chain.

Choose Sustainable Partners

Selecting suppliers with sustainable practices enhances supply chain transparency, ethics, and environmental impact. This mitigates risks associated with environmental issues, labor practices, and substandard quality. Prioritize suppliers with certifications related to sustainability and social responsibility.

By applying these strategies, businesses can transform their supply chain into a well-oiled, responsive machine that delivers maximum value. Optimizing the linkages from raw materials to final delivery delights customers, reduces waste, and positions your company for long-term success.

With robust supply chain management, you have the foundation to provide world-class products and services.